MOVINGLight® DLP Ceramic 3D Printers

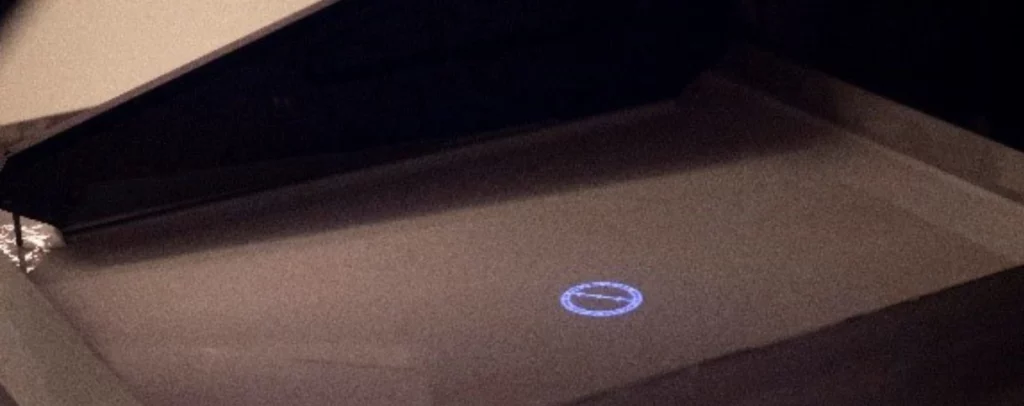

Ceramic 3D printing enters a new era with the CERAM PRO range of ceramic 3D printers from Prodways Machines. Featuring MOVINGLight® DLP technology, the process uses one or two moving projectors to ensure high printing speeds while maintaining consistent resolution up to 42 μm per pixel across the entire build platform. Designed for a wide range of ceramic and industrial applications, this series of ceramic 3D printers opens up new possibilities, particularly in the field of investment casting.

CERAM PRO Ceramic 3D Printers

CERAM PRO 365: A Turnkey Solution for Ceramic 3D Printing

- Single DLP head

- Available in 365 nm wavelength

- Compatible with TETHON 3D SILICA SICAST 1200 and ALUMINA A100 resins

- Build platform (LxW): From 66×41 mm to 264×328 mm

- Projector Power: 130 mW/cm² for 365 nm

CERAM PRO 385: Ceramic 3D printer, operating at 385 nm wavelength

- Single DLP head

- Available in 385 nm wavelength

- Compatible with open parameters

- Max. Build envelope size (LxWxH): 300x445x350 mm | 10.3×12.9×13.7 inches

- Projector Power: 90mW/cm² for 385 nm

CERAM PRO 385 +: Faster than the CERAM PRO 385

- Dual DLP heads for faster throughput

- Available in 385 nm wavelenght

- Compatible with open parameters

- Projector Power: 90 mW/ cm² for 385 nm

- Max. Build envelope size (LxWxH): 300 x 445 x 350 mm | 10.3 x 12.9 x 13.7 inches

CERAM PRO 405: Ceramic 3D printer, operating at 405 nm wavelength

- Single DLP head

- Available in 405 nm wavelength

- Compatible with open parameters

- Max. Build envelope size (LxWxH): 300 x 445 x 350 mm | 10.3 x 12.9 x 13.7 inches

- Projector Power : 90 mW / cm² for 405 nm

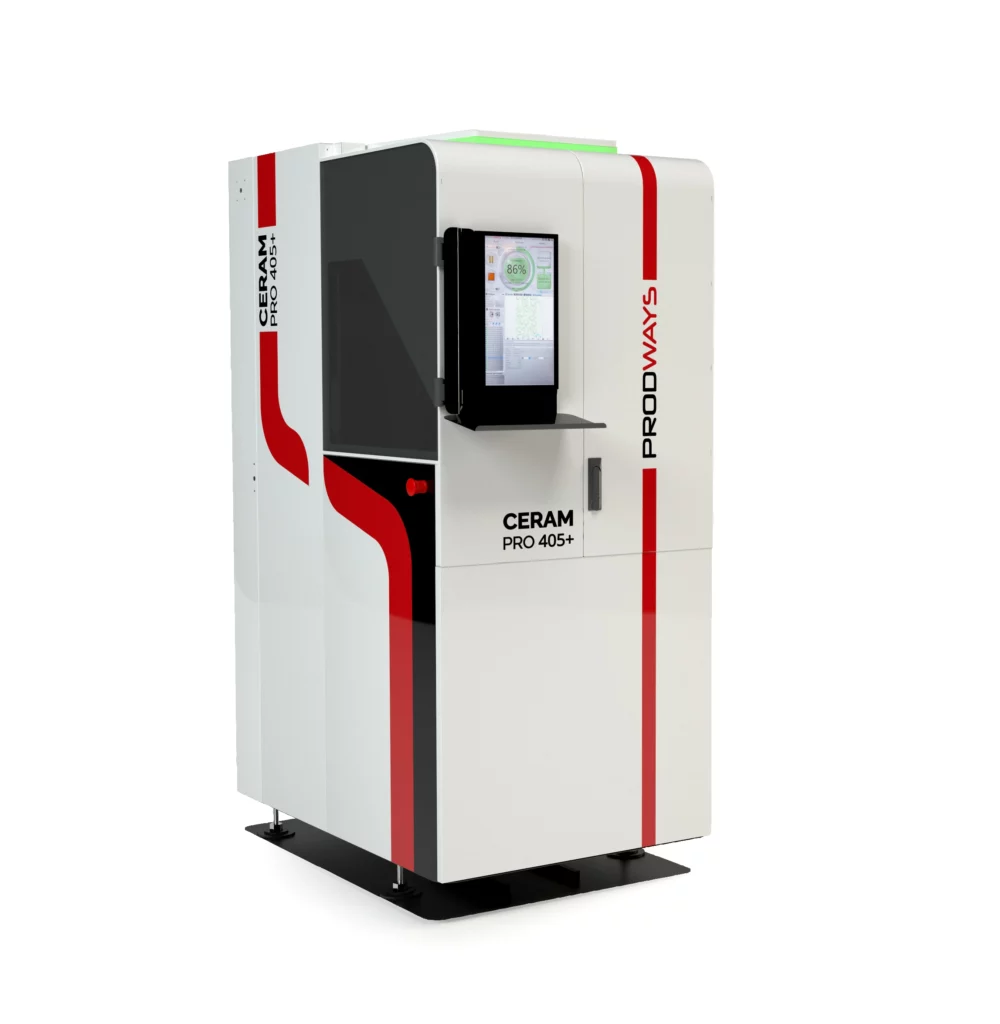

CERAM PRO 405 +: Faster than the CERAM PRO 405

- Dual DLP heads

- Available in 405 nm wavelength

- Compatible with open parameters

- Max. Build envelope size (LxWxH): 300 x 445 x 350 mm | 10.3 x 12.9 x 13.7 inches

- Projector Power : 90 mW/cm² for 405 nm

Ceramic 3D Printing: Optimized Production with CERAM PRO

CERAM PRO ceramic 3D printers are designed to adapt to the needs of each project. Their top-down modular build platform optimizes the ceramic printing process, enabling a maximum production capacity of 300 x 445 x 350 mm. With this large build area, it becomes possible to print a high volume of parts simultaneously, ensuring fast and efficient production even for the most demanding industrial applications.

CERAM PRO: Ceramic 3D Printers with Open Parameters

While its intuitive interface ensures immediate usability and an optimized workflow, the CERAM PRO range stands out with its open parameters, allowing the use of any ceramic material as well as resins optimized for the CERAM PRO 365 from our partner SINTX Technologies:

ALUMINA PHOTX A100 : This versatile material combines fast curing and excellent mechanical properties. It withstands extreme temperatures without degradation and is highly resistant to corrosion, making it ideal for a wide range of industrial applications.

SILICA SiCast 1200 : This material offers excellent green strength and minimal densification after sintering. It is specially designed for lost-wax casting, particularly for superalloys.

MOVINGLight® Ceramic 3D Printing: For Advanced Industries

Designed for advanced industries, CERAM PRO ceramic 3D printers produce complex parts with tight tolerances. Thanks to MOVINGLight® DLP ceramic 3D printing, they ensure strength, precision, and durability offering an innovative alternative to traditional methods and delivering solutions for multiple sectors:

- Investment Casting: Faster production and enhanced precision for ceramic molds.

- Aerospace & Defense: Lightweight components with complex geometries.

- Automotive: Design flexibility and shorter development cycles.

- R&D: Thermal stability and precision for advanced testing.

- Energy, Oil & Gas: Resistance to extreme environments.