Share this article

Customized healthcare through 3D printing

Medical

The use of 3D printing in the medical industry has become increasingly significant, especially in the wake of the COVID-19 pandemic. While 3D printing is often associated with prototyping, it has proven to be useful in the design and fabrication of medical devices, such as face shields and other protective gear, for hospitals and healthcare workers. However, 3D printing has been an important tool in the field of dentistry for many years. Its cutting-edge technology offers unparalleled flexibility and enables faster, more effective access to dental care.

3D printing and dentistry : Getting a beautiful smile faster is possible!

3D printing has enabled dentists and orthodontists to digitalize a significant portion of their tasks, providing greater comfort and cost savings for patients. This technology is particularly useful in creating complex forms, such as 3D models for bridges, crowns, and surgical guides for dental implants. Dentists can now produce high-quality models and guides in record time, resulting in faster and more efficient treatments for patients, while also reducing the number of visits to the office and production costs for practitioners.

One example of the benefits of 3D printing in dentistry is the production of custom teeth aligners for teeth straightening. The technology allows for the production of models to thermoform aligners that are perfectly adapted to each individual’s unique dental issues. This is a significant breakthrough for dentists and orthodontists, as only 3D printing can reliably produce these aligners so quickly.

Another major advantage is the speed of the process, which goes from digital impression to the delivery of perfectly fitting aligners, avoiding the need for multiple appointments with the practitioner. Additionally, 3D printing allows for the prefabrication of each patient’s custom aligners, adapted to the evolution of their teeth, which can be directly delivered to them. This significantly reduces the time and cost of treatment for patients.

Hear better, more comfortably: Customized hearing

3D printing in audiology has also disrupted traditional methods. Comfort is a critical criterion for hearing aid users, making the concept of customization crucial. With 3d printed hearing aids, we can obtain an appliance that perfectly fits the curves of their ear canal, thanks to a rapid impression-taking process. This is also ideal for replacing custom-made ear tips that are damaged or broken and require quick replacement.

The process involves scanning the ear impressions with a scanner, generating a 3D file of the ear canal, which is then sent directly to the manufacturer. This results in improved technical precision, reduced logistics costs, and a much more qualitative final result. Patients report greater satisfaction with this new process, especially during the successive COVID-19 lockdowns, which led to significantly reduced waiting times.

In summary, 3D printing is revolutionizing the healthcare industry by improving manufacturing processes in many areas, reducing costs and waiting times, and providing precise, high-quality products tailored to each individual. With the advent of new biocompatible materials, 3D printing may soon be used to print parts for the inside of the body, such as human tissue and skin cells, potentially becoming an alternative to traditional organ transplantation. The possibilities are endless.

Want to learn more? Get in touch with us or our experts.

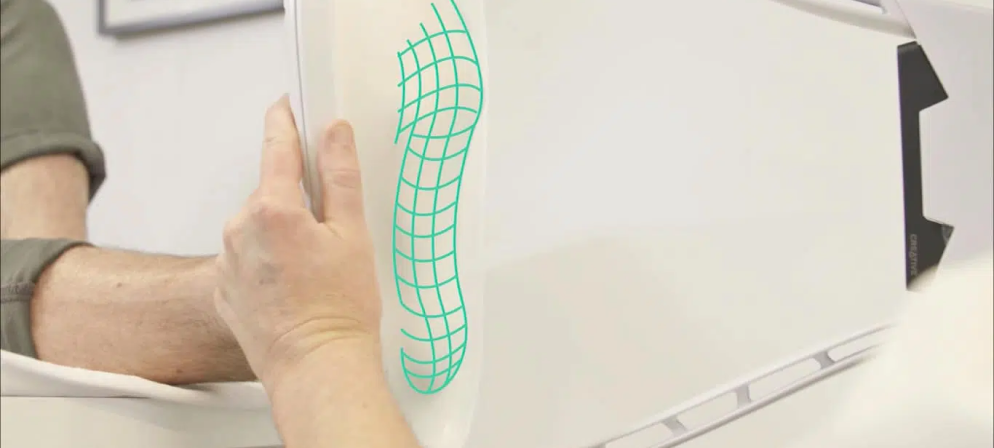

3D printing at the service of podiatrists

The use of 3D printing in healthcare has revolutionized various fields, including dentistry, audiology, podiatry, and surgery. In podiatry, the process involves a scan of the foot, which is saved in a 3D file and used to manufacture custom-made soles in the workshop. This process provides a competitive advantage for podiatrists, who can offer fast and customized creation of soles.

Additionally, 3D printing has collaborated with 3D orthopedic specialists from Handicap International to develop custom-made prostheses and make rehabilitation more accessible. This technology has also been of great assistance in surgery, where replicas of organs are created to anticipate operations. These replicas are known as “surgical pedagogical simulators” and are also used by surgeons and students to train and refine their gestures for future interventions.

The use of 3D printing in the medical industry has reduced costs and waiting times, making healthcare more accessible and efficient. With the advent of new biocompatible materials, the potential for printing parts for the inside of the body, such as human tissue and skin cells, is becoming a possibility. 3D printing may become a viable alternative to transplants, providing new opportunities for patient care.

You want to learn more ? contact our experts.

Discover more

-

History

The fascinating history of 3D printing

Since its humble beginnings in the 1980s, 3D printing has come a long way, completely revolutionizing the way we design and create objects.

Read more

-

Bureau d’études

Using metal 3D printing to produce components in Inconel 718: an innovative and efficient solution!

Die Geschichte von Inconel reicht zurück bis in die 1940er Jahre, als es für den Einsatz in Reaktoren entwickelt wurde.

Read more

-

Interview Client

Hearing health: Welding Alloys takes care of its employees with Protac hearing protection

Noise at work can cause deafness, as well as other illnesses such as stress and fatigue. At Welding Alloys, employees are exposed to daily noise levels of up to 100 decibels.

Read more